Steel cut to your specs, including custom cuts

Serving Connecticut, Massachusetts, and Beyond

Contact Us

Watch our brief video to learn more about Windsor Steel

Precision custom commercial steel cutting in Connecticut, Massachusetts & the northeast

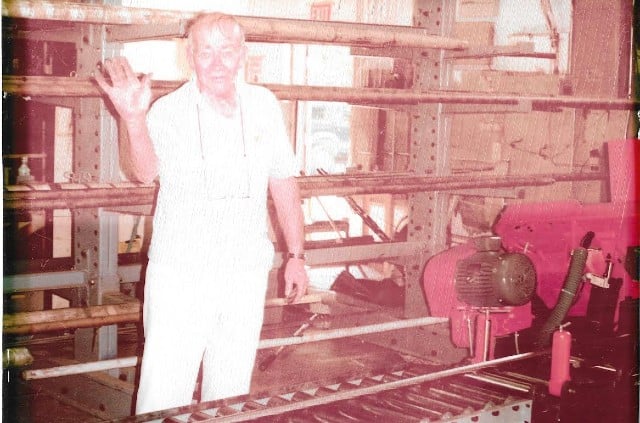

Family Business. Family Values. Family Dedication.

Since 1972, our family-owned company has had one goal – Customer Satisfaction. We are Connecticut’s steel-cutting experts. Our wide range of equipment on our shop floor means we can fill almost any order. If you need your steel with angle cuts, we have the saws for that.

Windsor Steel employees have been with us for over a decade (some for over four decades), so anyone can answer your questions on the phone or while making a delivery.

We offer same-day pick-up for urgent orders.

Steel Cutting Capabilities

Our plate saws allow us to handle non-conventional widths at 12-foot lengths

Automatic saws let us cut large multiple pieces in a timely manner

Have large multiple blocks? We can cut them to your specs, saving you man hours

Why Choose Windsor Steel?

Delivery Options

- One-day delivery

- Two-day delivery

- Customer pick-up

- Delivery by Windsor Steel trucks, Common Carrier, or UPS

- Ask about our same-day, expedited pickup service

- Over night delivery where available

Custom Ordering

- Custom Cutting

- Cut pieces or full bar lengths

- Multiple delivery options

- Specialized Packaging

Our Team and Clientele

We have the capacity to meet the needs of our clients – From one-man shops to multi-million dollar corporations. In addition, our knowledgeable staff is here to provide timely updates on your orders ASAP.

Some of the industries we serve:

- Aerospace and Automotive

- Medical and Dental

- Military and Plastics

- Technology and R & D

- Commercial Industries